Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

How can we help you?

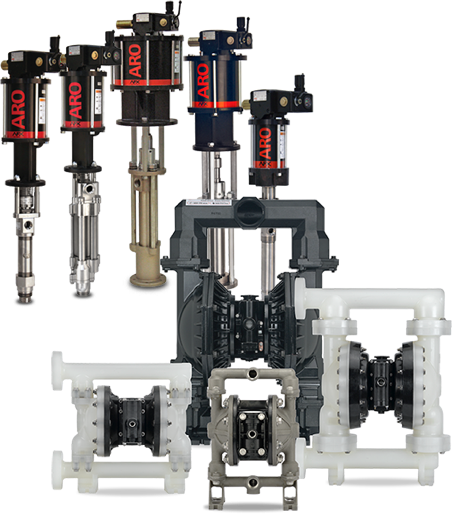

Industrial paints and protective coatings need a system that can ensure your materials flow consistently and smoothly. That’s why experts who design systems that handle the transfer of these high-solids materials trust ARO diaphragm pumps and piston pumps to maintain a steady stream. Learn more about air operated diaphragm pumps, electric diaphragm pumps and piston pumps.

High-performance coatings contain pigments, resins, and other filler material that improve surface adhesion and workability. But they also have increased abrasive properties that can lead to extended downtime. ARO piston pumps and diaphragm pumps combine lasting durability with expert engineering to give you a paint transfer pump capable of resisting wear while providing consistent flow and perfect finishes, in any type of industrial paint or coating application.

Designed to meet the demands of constant use in abrasive-heavy industries without wearing down, ARO® piston pumps can be configured with materials of construction and packing materials that deliver superior resistance.

ARO piston pumps and diaphragm pumps deliver the power, adaptability, and dependability you need in an airless paint pump or industrial coating system. Keep things moving with our reliable pump features:

| 6” stroke delivers greater displacement with less wear than 4” stroke pumps | Time-tested design that’s been proven for long-term use | ||

| Fewer moving parts lead to easier service and safer operation | Stainless steel or carbon steel construction available depending on your application |

ABOUT ARO

ARO is Fluid Intelligence and a leading worldwide manufacturer of fluid handling products, including diaphragm pumps and piston pistons, that are expertly engineered to deliver performance and serviceability, enabling our customers to achieve the best total cost of ownership.

209 N. Main Street

Bryan, Ohio 43506 | 800-495-0276