Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

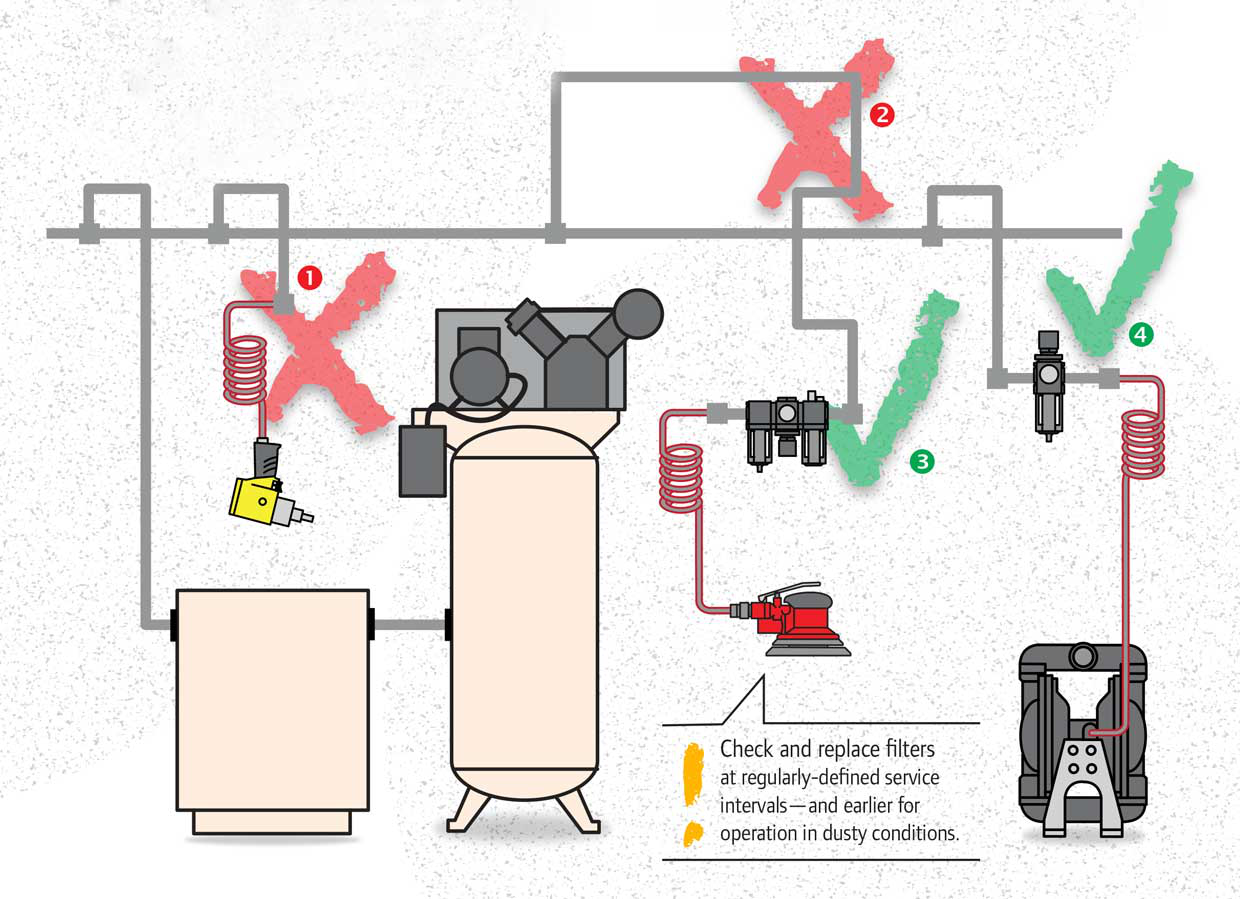

Unfiltered contaminants in your plant’s air lines increase in volume up to 800% under normal air system pressures of 100 PSI, damaging air tools, pumps, and other equipment attached to your plant’s air system.

Installing the right filters in the right locations, as closely as possible to the point-of-use for each air tool or piece of equipment, helps you eliminate the high costs of unscheduled production downtime and cuts your plant service costs by extending the service life of air tools and equipment in your plant.

Contaminated air with moisture, particles, and oil damages vanes,bearings, seals, and other internal surfaces of air tools andequipment, shortening service life and risking costlyunscheduled downtime. In painting and coating applications, moisture,and particle contamination increases product scrap rates due todefects in surface finishes.

ABOUT ARO

ARO is Fluid Intelligence and a leading worldwide manufacturer of fluid handling products that are expertly engineered to deliver performance and serviceability, enabling our customers to achieve the best total cost of ownership.

209 N. Main Street

Bryan, Ohio 43506 | 800-495-0276